Aflasafe is a 100% natural product for controlling poisonous Aspergilus flavus (A flavus) in food crops, including maize. According to Kenya Agricultural and Livestock Organization crops researcher Eliud Njoroge, Aflasafe pushes out aflatoxin-producing types of A flavus. Alfasafe is mainly roasted sterile sorghum (99.7% of the product), coated with four atoxigenic i.e. (non-poison producing) types of A flavus native to Kenya. To avoid confusion with sorghum to eat, Aflasafe is dyed blue using food color.

READ ALSO: Aflasafe to help Kenyan farmers to tame food losses to aflatoxins

Aflatoxin is a toxin produced by a fungus that grows on certain crops, such as maize and groundnuts. Consumption of high levels of aflatoxin can be fatal, and chronic exposure has been linked to liver cancer, suppressed immune response, and child stunting. Maize is a staple food in Kenya and is a major source of aflatoxin exposure in the country.

READ ALSO: Applying Aflasafe ahead of flowerings stops aflatoxin

Maize handling after harvesting is key in determining the quality of the Maize grain and the final products. If mismanaged, it may easily lead to aflatoxin contamination, a poisonous mould content that arises from improperly dried maize.

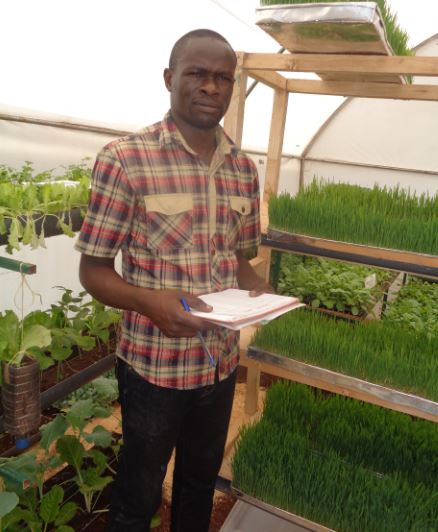

Applying Aflasafe ahead of flowering stops aflatoxin. PHOTO/FARMBIZ AFRICA

How does Alfasafe work?

After broadcasting and exposure to sufficient moisture, the friendly Aflasafe fungi grow out, and the blue-colored sorghum grains will now be covered with green spores. These growing fungi will first appear as white fuzz and later appear as green fuzz containing millions of spores. The green spores will eventually spread to the crop, carried by wind and insects in the manner that aflatoxin-producing fungi are spread.

READ ALSO: Aflasafe ends aflatoxin agony

Njoroge says Aflasafe can be used with intercropping. It will not harm other crops because it is a natural product made from fungi obtained from Kenya’s crops and soils. Intercropping does not affect Aflasafe’s performance.

Directions for using Alfasafe

- Prior to broadcasting Alfasafe, the plot should be weeded, fertilizer applied, and all other agricultural practices carried out in the field.

- Broadcast Alfasafe by hand 2-3 weeks before flowerinf at the rate of 10 kg per ha (4 kg per acre). If possible, apply Alfasafe after rains, or when rains are forecasted, or when the soil is moist.

- Ensure that Alfasafe stays on the soil surface. For the spores to grow, they must be above the ground. Therefore, do not carry out any operation that will bury Alfasafe under the soil after application. Such operations should be done in the step 1 above.

- 5 to 10 days after broadcasting Alfasafe, visit the field and observe the color of the carrier grains. There should be a greenish growth on some or all sorghum carrier grains if soil moisture is adequate. If there is no greenish growth, return to the field after 3-5 days and check again.

- To realize Alfasafe’s full potential, ensure you follow good agricultural, harvest and post-harvest practices, and follow all the instructions and precautions on the pack.

For more information contact +254 20 422 3350 or email This email address is being protected from spambots. You need JavaScript enabled to view it.

Write comment (0 Comments)